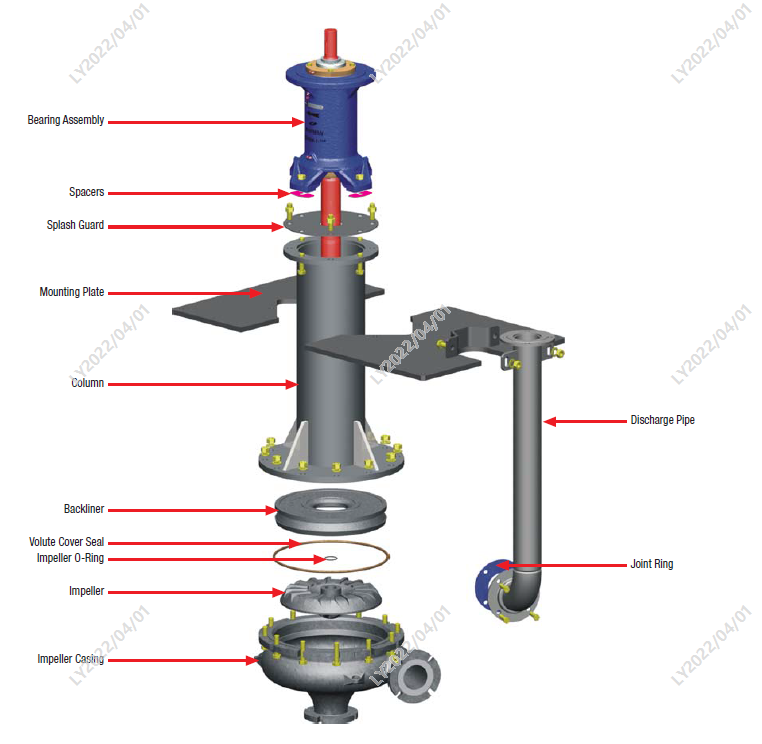

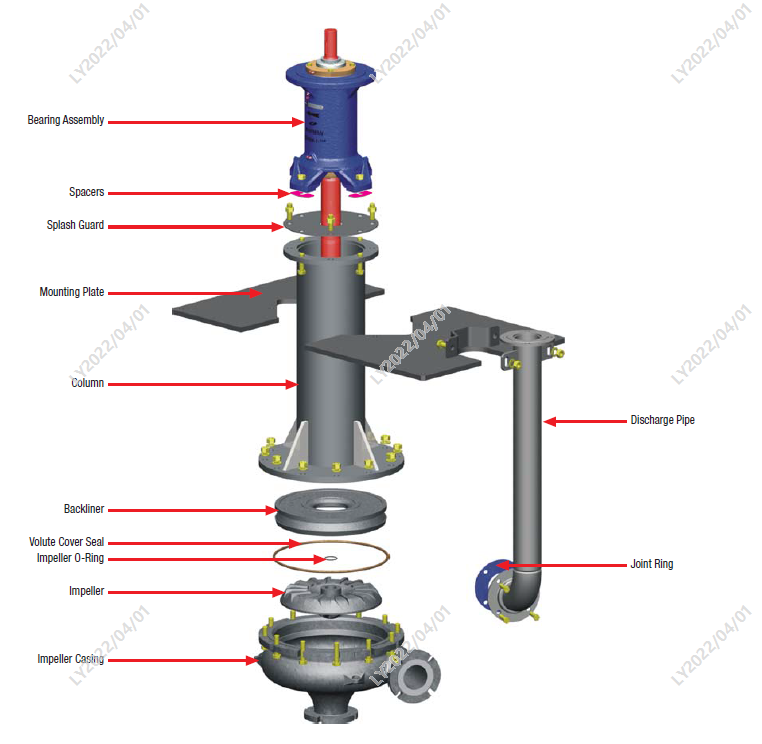

Note: For the Cyclo Sump Duty Pump, the standard shaft length range is from 900mm to 2100mm, and different submerged depth could be met by adding suction pipe.

Note: For the Cyclo Sump Duty Pump, the standard shaft length range is from 900mm to 2100mm, and different submerged depth could be met by adding suction pipe.

Note: For the Cyclo Sump Duty Pump, the standard shaft length range is from 900mm to 2100mm, and different submerged depth could be met by adding suction pipe.

Note: For the Cyclo Sump Duty Pump, the standard shaft length range is from 900mm to 2100mm, and different submerged depth could be met by adding suction pipe.