Damei Kingmech Pump Co., Ltd. is a reliable manufacturer, supplier, and factory of high-quality pumps, including canned pumps and centrifugal pumps. These pumps are essential in various industries for different applications.

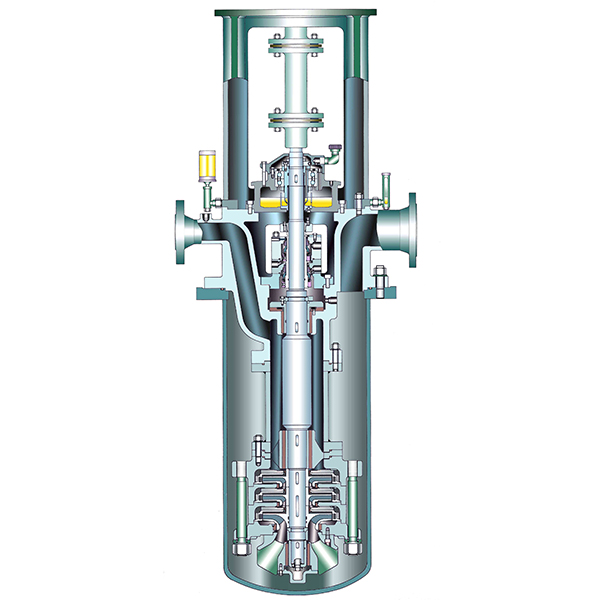

Canned pumps have a unique design in which the entire centrifugal pump is enclosed in a metal can to provide exceptional leakage protection. It is known for its energy efficiency, high reliability, and low maintenance costs, making it a popular choice for industrial processes.

On the other hand, centrifugal pumps are commonly used in water treatment plants, construction sites, and farms. These pumps are designed for high flow rates and low-to-medium head applications, providing a continuous flow of liquids in a cost-effective manner.

Damei Kingmech Pump Co., Ltd. is committed to providing exceptional quality and innovative solutions to its customers in China and other countries. Our team of experts ensures that each pump is designed, manufactured, and tested to meet the highest industry standards. Contact us now for all your pump needs.